Equipment - 3.1 Maintenance and calibration

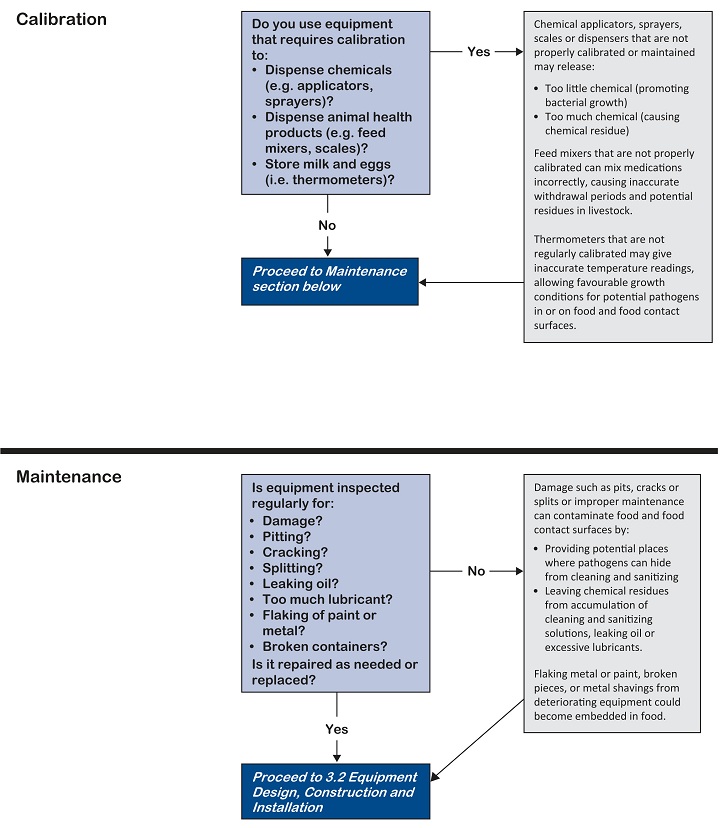

Food, livestock or poultry may become contaminated if a regular maintenance and calibration schedule is not in place for production equipment.

This good agricultural practice applies to all farms.

What needs to be done

To protect the safety of food, livestock and poultry, equipment maintenance and calibration practices must be performed at the required frequency and according to the equipment manufacturer’s specifications.

How to do it:

- Identify production equipment critical to food safety that requires maintenance and calibration. Such as sprayers, manure spreaders, scales, conveyors, flume washers, feed mixers, dispensers, medicators, refrigerators, coolers and temperature-monitoring devices

- Create maintenance and calibration schedules for each identified piece of equipment

- Calibrate equipment at recommended frequencies following manufacturers’ instructions to ensure measuring is performed accurately

- Perform maintenance as detailed in the manufacturers’ operating manuals, such as lubricating with proper lubricants, changing oil and filters, replacing parts, tightening loose screws and adjusting belts

- Visually inspect equipment for potential problems such as cracked or pitted surfaces and leaking oil

- Repair or discard damaged equipment, crates and containers

- Use food-grade lubricants, paints and oils if these materials are likely to come into contact with ready-to-eat product such as fresh produce, eggs or milk

In general

When food, livestock or poultry have become contaminated due to equipment failure, seek advice on the best course of action (for example, observance of withdrawal times, cleaning and sanitizing or disposal options).

Records to keep

Use the Equipment maintenance and calibration record or create your own record that includes:

- Date

- Equipment

- Action performed

- Reason for action (for example regular maintenance, equipment failure)

- Initials of worker

If you have an audit

Be prepared for the auditor to:

- Review records of all maintenance and calibration activities for equipment critical to food safety

- Observe whether only food-grade approved lubricants and paints are used on equipment that come into direct contact with food

Laws and regulations

Legal requirements for refrigeration are usually related to disease control, usually to keep microbial populations to a minimum growth potential. The Milk Industry Act, R.S.B.C. 1996, c. 289, Milk Industry Standards Regulation, Reg. 464/81, s. 9 prohibits a producer from selling or offering for sale milk that has not been cooled in a farm holding tank to a temperature of 4°C or lower, after each milking, and not less than 0°C, and maintained in that temperature range until collected by a licensed tank milk receiver.

Milk Industry Standards Regulation, Reg. 464/81, s. 38 under the Milk Industry Act specifies calibration and measuring requirements for the farm holding tank.