Water - 4.2 Water treatment

If poor quality water is used without being treated first, or water quality is not maintained during use (such as with dump tanks), contaminants can be passed to livestock, poultry and food. Improperly treated water can also be a source of contamination.

This good agricultural practice applies to farms with poor water quality.

What needs to be done

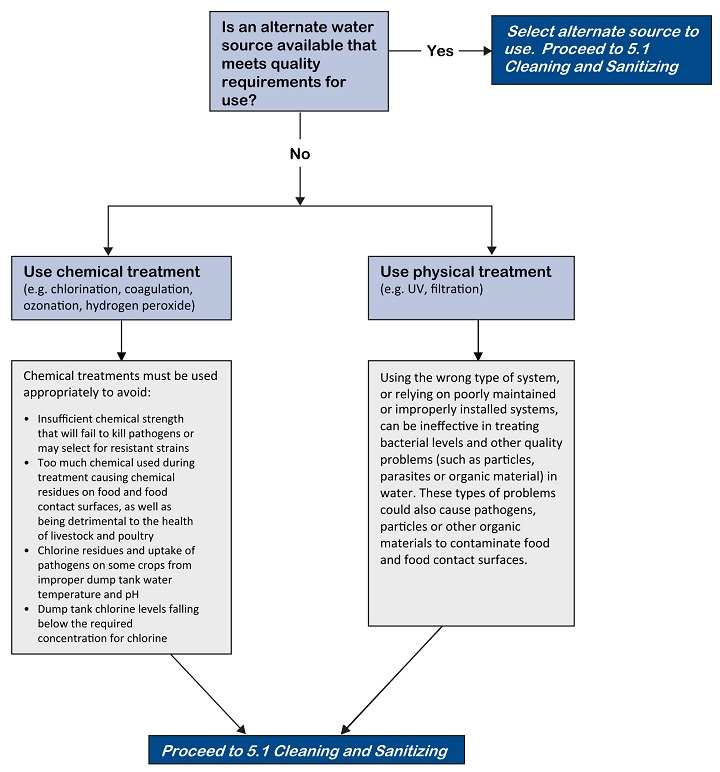

To protect the safety of food, livestock or poultry, treat water as required to maintain its quality or use an alternative source.

How to do it

Choose the right method of water treatment. Make sure the type of water treatment chosen is the right one for the particular situation. Consult water quality professionals for more information on water treatment options.

A number of water treatment methods are available and can be used alone or in combination with several other treatment processes.

Physical water treatment

Filtration is the process of treating water contaminated with substances such as dirt or organic matter. For example, sand filters will remove large particles from the water. Granular activated carbon (GAC) filters, commonly known as charcoal filters, will filter particulate matter from the water and will also adsorb (soak up) dissolved organic matter and other contaminants. Membrane filtration is the most effective method for removing parasites such as Giardia and Cryptosporidium.

Ultraviolet (UV) light is a non-chemical method for killing micro-organisms such as bacteria, viruses (not retroviruses and rotaviruses), spores and cysts.

Chemical water treatment

Coagulating water is the process of adding chemicals to water to make dissolved or suspended particles bind together and settle out. This process reduces the level of organic compounds, dissolved phosphorus, colour, iron and suspended particles.

Chlorination is the process of adding chlorine to water to kill bacteria and viruses but not parasites such as Giardia and Cryptosporidium. Two types of water chlorination – shock chlorination and continuous chlorination – are used in water treatment. Continuous chlorination (used for treating dump tank water) is a process of adding chlorine to water continuously to maintain a certain level of free chlorine in the water at all times.

Treating with shock chlorination: Shock chlorination, used for treatment of wells, is the process of flushing a well and water system with a chlorine solution. After a set amount of contact time of letting the chlorine solution shock the system the system is flushed to get rid of the chlorine solution. A well water sample is then sent to the lab for total coliforms and E. coli testing to confirm that the water is safe to use. Continue to regularly monitor your water source for quality.

Treating with continuous chlorination: A continuous chlorination method (for example, a dump tank) must be regularly monitored at pre-determined intervals for free chlorine and pH levels. The recommended chlorine and pH levels for a produce dump tank are 100 to 150 ppm chlorine and 6.0 to 7.5 pH. Regular monitoring of chlorine levels is done by using an automatic dispensing chlorinator. Verify the settings by manually testing with a test kit to confirm adequate chlorine and pH levels are being maintained.

Ozonation is the process of adding ozone to water to kill bacteria, viruses, parasites, mould and yeast spores. Ozone is a very efficient disinfectant and breaks down completely in water. However, due to its instability, it requires a high level of maintenance and operator skill.

Hydrogen eroxide is a chemical added to water to kill bacteria, viruses and fungi. It is used along with ozone in what is called peroxone disinfection. As this disinfection process does not provide a measurable disinfectant residual it is not a recommended method for treating small water systems.

Biological water treatment

Biological water treatment is ideally suited to treat water that is highly coloured and has high dissolved organic carbon (DOC) and nutrient levels. It uses a natural ecosystem that removes colour and dissolved organic matter, but not micro-organisms. The treatment involves the use of naturally occurring micro organisms in the surface water to improve water quality.

Ask your chemical or water treatment supplier for approved water treatment aids, or refer to Water for agricultural prodcution (Agriculture and Agri-Food Canada)

Monitor water quality after treatment

Monitor water quality to ensure treatment is effective. When a water treatment method or system has been installed or repaired take a water sample to a lab to test for Total coliforms, Fecal coliforms and E. coli bacteria to ensure it is working effectively.

Re-test water at pre-determined frequencies to ensure water quality.

Where chlorine levels need to be maintained, monitor water regularly for chlorine and pH levels.

Records to keep

Use Sample G: Water treatment record as a template, or create your own record that includes:

- Date and/or time of treatment

- Chemical used, including amount and concentration

- Monitoring result (for example, chlorine level, pH)

- Signature or initial of worker performing treatment/testing

Lab-test results for water quality.

If you have an audit

Be prepared for the auditor to review:

- Water treatment records

- Water quality lab-test results

- Training records for workers responsible for water treatment

Laws and regulations

There are few laws that impact on food safety regulating the treatment of water to be used in agricultural production. Generally, these requirements are laid out in laws regarding the processing of meat, fish and other food products, which are outside the scope of this document.

Although B.C. legislation does not set out requirements for water treatment, the Drinking Water Protection Act, S.B.C. 2001, c. 9, s. 6 states that a water supplier must provide users served by the water supply system with drinking water that is both potable and that meets any additional requirements set by the regulation or by the water system’s operating permit.

The Drinking Water Protection Regulation, Reg. 200/03, s. 3.1 states that a small community water system that serves less than 500 individuals is exempt from s. 6 of the Act if each recipient of the water from the system has a point of entry or point of use treatment system that makes the water potable. Check with your local drinking water officer or health inspector for recommended water treatment procedures.